Belt dryer for malted milk powder industrial food freeze industrial continuous vacuum belt drying

- Price

- US $84500-85000

- Model

- LTDG-20

- MOQ

- 1 piece

Item specifics

- Power

- 65Kw, 380V±10%, 50HZ, 3Phase, 5Wire

- Vacuum function

- 9.6kw

- Vacuum pump speed

- 90m3/h+90m3/h=180m3/h

- Roots pump speed

- 540 m3/h

- Power Units

- 3.7+3.7+2.2=9.6kw

- Lock method

- Rotate and locking type by handle

- Direction of opening door

- open right (the user can choose)

- The roughness of chamber and door

- Ra≤0.6μm

- Insulation material

- Rubber insulation board/δ70mm

- Total weight

- 3800kg

Review

Description

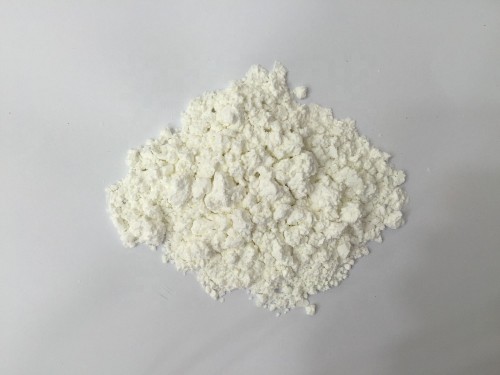

Belt dryer for malted milk powder industrial food freeze industrial continuous vacuum belt drying

Vacuum belt dryer is a continuous infeed and discharge vacuum drying equipment. Liquid product is conveyed into dryer body by infeed pump, evenly spread on belts by distribution device. Under high vacuum, the boiling point of the liquid is lowered; water in the liquid material is evaporated. Belts move on the heating plates evenly. Steam, hot water, hot oil can be used as heating media. With the moving of the belts, the product goes through from the beginning evaporating, drying, cooling to discharging in the end. The temperature decreases through this process, and can be adjusted for different products. Special vacuum crusher is equipped at the discharge end to produce different size end product. The dry powder or granule product can be automatically packed or continue with subsequent process.

EQUIPMENT ADVANTAGE:

1.Less labor cost and energy consumption

2.Little loss of product and solvent recycling possible

3.PLC automatic control system & CIP cleaning system

4.Good solubility & excellent quality of the products

5.Continuous feed-in, dry, granulate, discharge in vacuum state

6.Completely closed system and no contamination

7.Adjustable drying temperature (30-150℃)& drying time (30-60min)

8.GMP standards

Vacuum belt dryer is a continuous infeed and discharge vacuum drying equipment. Liquid product is conveyed into dryer body by infeed pump, evenly spread on belts by distribution device. Under high vacuum, the boiling point of the liquid is lowered; water in the liquid material is evaporated. Belts move on the heating plates evenly. Steam, hot water, hot oil can be used as heating media. With the moving of the belts, the product goes through from the beginning evaporating, drying, cooling to discharging in the end. The temperature decreases through this process, and can be adjusted for different products. Special vacuum crusher is equipped at the discharge end to produce different size end product. The dry powder or granule product can be automatically packed or continue with subsequent process.

EQUIPMENT ADVANTAGE:

1.Less labor cost and energy consumption

2.Little loss of product and solvent recycling possible

3.PLC automatic control system & CIP cleaning system

4.Good solubility & excellent quality of the products

5.Continuous feed-in, dry, granulate, discharge in vacuum state

6.Completely closed system and no contamination

7.Adjustable drying temperature (30-150℃)& drying time (30-60min)

8.GMP standards

EQUIPMENT ADVANTAGE:

1.Less labor cost and energy consumption

2.Little loss of product and solvent recycling possible

3.PLC automatic control system & CIP cleaning system

4.Good solubility & excellent quality of the products

5.Continuous feed-in, dry, granulate, discharge in vacuum state

6.Completely closed system and no contamination

7.Adjustable drying temperature (30-150℃)& drying time (30-60min)

8.GMP standards