LPG-300 milk powder spray dryer machine price for extract aluminium

- Price

- US $85000

- Model

- LPG-300

- MOQ

- 1 piece

Item specifics

- Water Evaporation

- 300kg/h(under drying temperature 220-280 ℃)

- Method of Atomizing

- High Speed Centrifugal Atomizer (mechanical drive

- Revolution of atomizer(rpm)

- 16000

- Diameter of Atomizing disc (mm)

- 150

- Dried Powder Recovery Rate (%)

- Around≥95

- Length of Covered Area(m)

- 9

- Width of Covered Area(m)

- 7

- Height of Tower Body(m)

- 9

- Hoisting height of Nozzle(m)

- 3.2

- Air input Temp

- 140~350℃

- Air output Temp

- 80~90℃

- Electric Heating Power

- According to processing way

Review

Description

LPG-300 milk powder spray dryer machine price for extract aluminium

Machine Description:

Spray drying is the most wide applied process in liquid process shaping and drying industry.The drying technology is most suitable for producing solid powder or practical products from liquid material,such as :solution,emulsion,suspension and pumpable paste states.For this reason,the particle size and distribution of the final products,residual water contents,mass density and the particle shape must meet the precise standard,spray drying is one of the most desired technologies.

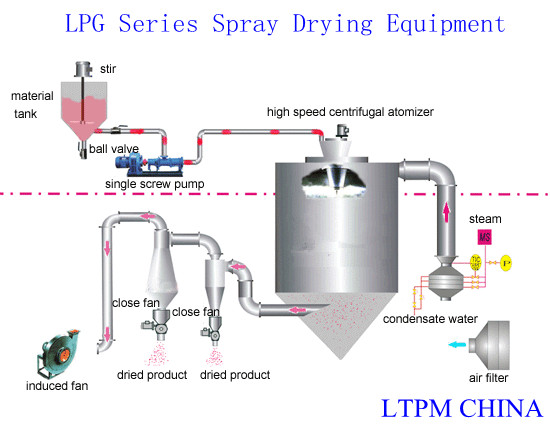

Working Principle:

After air gets filtered and heated,it enters into an air distributor on the top of the dryer.The hot air enters into the drying room in a uniformly spiral form.Passing through the high speed centrifugal sprayer on the top of the tower,the material liquid will rotate and be sprayed into the extremely fine mist liquid beads.Through a very short time of contacting the hot air,materials get dried.The final products discharge continuously from the bottom of the drying tower and from the cyclones.The waste gas will be discharged from blower.

Features:

High drying speed atomizes material into liquid,the surface of the material increase greatly.It only takes few seconds to evaporate 95-98% water in a hot air flow.This is especially suitable for drying the heat sensitive materials.

The final product has features of good uniformity,flow ability,and solubility.It is in a high purity and quality as well.

The production procedure is simple,operation and control are easy.For material contains 40-60% water(special material can contain more than 90%),it can be dried into powder or particles once a time.After the drying process,there is no need for smashing and sorting,so as to reduce the operation procedures in the production and to enhance the product purity.The product particle diameters,losseness and water contents can be adjusted through changing the operation condition whining a certain range.It is very convenient to carry out control and management.

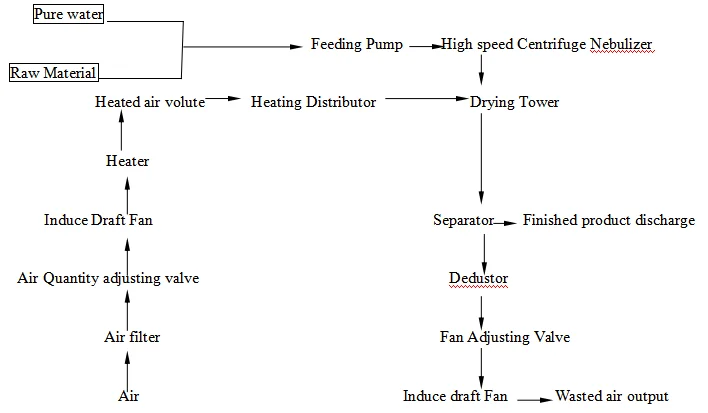

Drying Process:

Controlling System:

The electronic box is made from SS304, and PLC is adopted for controlling system. All of the data are displayed on touch screen. And the main electronic parts are all imported brands.

Finished Products:

Alumina Powder Herbal Powder Egg Powder

Milk Powder Soy Sauce Powder Polyphenols

Main Techinical Data:

Item | Specification |

Water Evaporation | 300kg/h(under drying temperature 220-280 ℃) |

Method of Atomizing | High Speed Centrifugal Atomizer (mechanical drive or stepless frequency speed regulation is available) |

Revolution of atomizer(rpm) | 16000 |

Diameter of Atomizing disc (mm) | 150 |

Dried Powder Recovery Rate (%) | Around≥95 |

Length of Covered Area(m) | 9 |

Width of Covered Area(m) | 7 |

Height of Tower Body(m) | 9 |

Hoisting height of Nozzle(m) | 3.2 |

Air input Temp | 140~350℃ |

Air output Temp | 80~90℃ |

Electric Heating Power | According to processing way |

Notes: The evaporated amount of moisture is contingent upon the characteristics of the raw material, solid content and temperature of hot air at inlet and outlet. Customers can choose the heating method according to the conditions of the local energy source. | |

Machine Pictures: