LPG-1.5 Mini Milk spray drying machine equipment for egg

- Price

- US $5000

- Model

- LPG-1.5

- MOQ

- 1 piece

Item specifics

- Inlet temperature

- 100~280℃(Adjustable)

- Output temperature

- 100~150℃(adjustable)

- Water evaporation capacity

- 1500ml/H

- Max input capacity

- 2000ml/H

- Electricity heating power

- 3KW AC220V

- Fan

- 0.2KW Max air flow 5.6m3/min Max air pressure 102

- Air compressor

- 0.2KW Max air production capacity 4.2 m3/h

- Air pressure

- 2~3Bar

- Dimension

- 780 x 560 x 1300 ( mm )L x W x H

- Spray nozzle diameter

- 1.0mm

- Weight

- 125kgs

Review

Description

LPG-1.5 Mini Milk spray drying machine equipment for egg

Machine Description:

Apply to universities, Research Institute and food medicine chemical enterprise laboratory production of micro particles of all solutions such as emulsion or suspension with wide applicability, which is suitable for biological products, bio pesticides, enzymes and other compounds on the thermal sensitivity of drying.

Specific for the following areas: beverage flavors and colors of milk and egg products plants and vegetable extracts of pharmaceutical synthetic thermal plastic polymer material and resin aromatic blood products pottery and superconductor biochemical products dye soap and detergent food adhesive oxide bone meal and dentifrice etc..

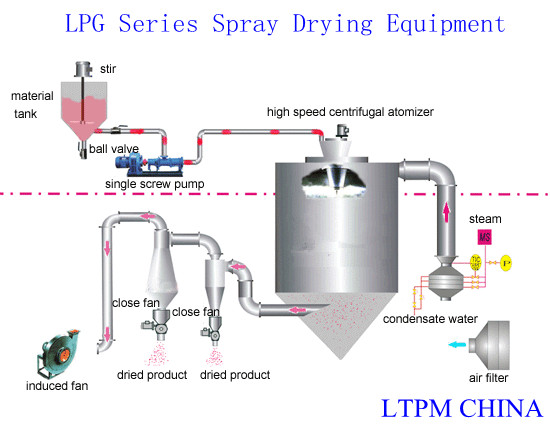

Working Principle:

Liquid material is pumped into the top installed rotary disc atomizer by mono pump and atomized into fine droplets inside the drying chamber. Heated and filtered hot air will be blown into the air distributor at the same time. The evenly and swirly distributed hot air completely contact with the droplets for heat transfer. In several seconds, the droplets will be dried into powder and sucked out into the cyclone for discharging via exhaust fan.

Features:

1.Dry faster, the general time is only 5-15 seconds, with instantaneous drying characteristics.

2.Materials take a very short period of time to complete the drying process, adapted to the dry thermosensitive materials, materials to maintain color, smell and taste.

3.Simplify the production process.The operational control is simple,which is suitable for control of production, wet 40-90% of the volume of liquid into a dry powder, reduce the crushing, screening processes.

4.All contact parts are made in SS304. for easy checking and operating purpose, all of the controllers and lights are equipped in one controller.

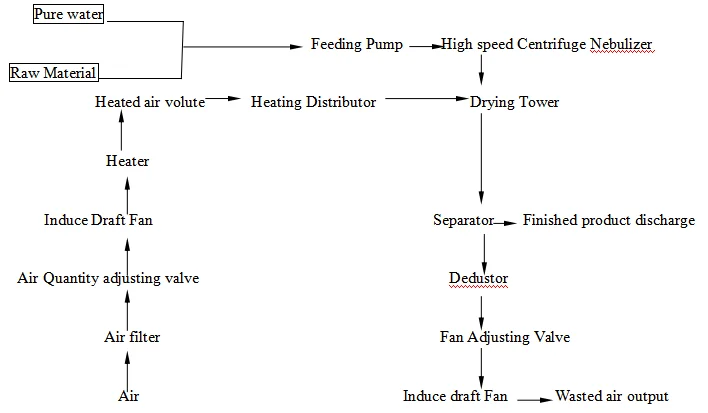

Drying Process:

Controlling System:

The electronic box is made from SS304, and PLC is adopted for controlling system. All of the data are displayed on touch screen. And the main electronic parts are all imported brands.

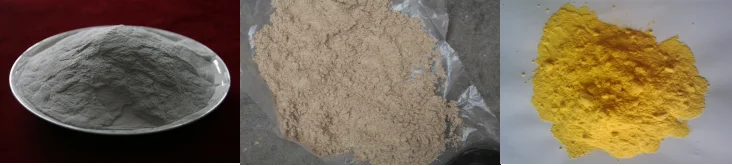

Finished Products:

Alumina Powder Herbal Powder Egg Powder

Milk Powder Soy Sauce Powder Polyphenols

Main Techinical Data:

Item | Specification |

Inlet temperature | 100~280℃(Adjustable) |

Output temperature | 100~150℃(adjustable) |

Water evaporation capacity | 1500ml/H |

Max input capacity | 2000ml/H |

Electricity heating power | 3KW AC220V |

Fan | 0.2KW Max air flow 5.6m3/min Max air pressure 1020Pa |

Air compressor | 0.2KW Max air production capacity 4.2 m3/h |

Air pressure | 2~3Bar |

Dimension | 780 x 560 x 1300 ( mm )L x W x H |

Spray nozzle diameter | 1.0mm |

Weight | 125kgs |

Item | Name | Brand | Qty. | Unit |

1 | Temperature controller | Delta | 1 | Set |

2 | PLC | Mitsubishi | 1 | Set |

3 | Peristaltic Pump | Sinuo | 1 | pc |

4 | Relay | Omron | 1 | pc |

5 | Fan | Shanghai | 1 | Set |

6 | Spray Gun | Shanghai | 1 | Pc |

7 | Clamp | Shanghai | 4 | pcs |

8 | Atomization chamber | Shanghai | 1 | pc |

9 | Separator | Shanghai | 1 | pc |

10 | PT100 Sensor | Shanghai | 2 | pcs |

11 | Compressor | Taiwan | 1 | pc |

12 | Material collector | Shanghai | 1 | pc |

13 | Waste collector | Shanghai | 1 | pc |

14 | Insulation | Shanghai | 1 | Set |

15 | Heater | Shanghai | 1 | pc |

16 | Speed adjusting module | Shanghai | 1 | pc |

17 | Solid relay | Mager | 1 | pc |

18 | Pressure regulating valve | Taiwan | 1 | pc |

19 | Touch screen | Kunlun | 1 | Set |

20 | 0.4kw inverter | Jintian | 1 | Set |

21 | 90 degree joint | Shanghai | 1 | pc |

22 | 20A Fuse | CHNT | 1 | pc |

23 | Fan | Sanxie | 2 | pc |

24 | Air exhausting pipe | Shanghai | 1 | pc |

25 | Air switch | CHTN | 1 | pc |

26 | Temperature sensor | Jiamin | 1 | pc |

32 | Peristaltic pipe | Shanghai | 1 | M |

Machine Pictures: