LPG-50 Automatic High Speed Spray Dryer Milk Powder for sale/ Spray Dryer Price

- Price

- US $37000

- Model

- LPG-50

- MOQ

- 1 piece

Item specifics

- Water Evaporation

- 50kg/h

- Method of Atomizing

- High Speed Centrifugal Atomizer (mechanical drive or stepless frequency speed regulation is available)

- Revolution of atomizer(rpm)

- 21500

- Diameter of Atomizing disc (mm)

- 120

- Dried Powder Recovery Rate (%)

- Around≥95

- Air input Temp

- 140~350℃

- Air output Temp

- 80~90℃

- Height of Tower Body(m)

- 5.5

- E-Heating Power

- 60kw

- Hoisting height of Nozzle(m)

- 2.5

Review

Description

LPG-50 Automatic High Speed Centrifugal Spray Drying Machine

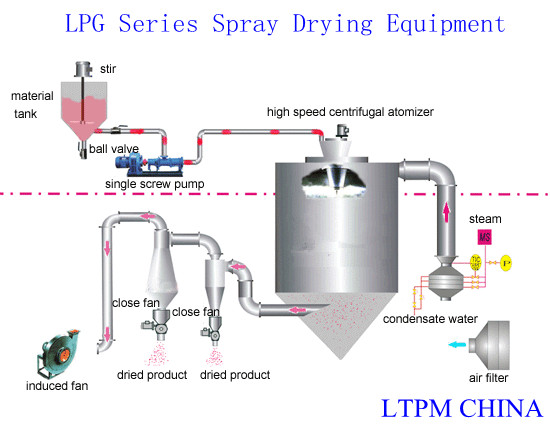

LPG-50 includes:

1. Whole production line as the attached drawing shows.

2. Operation flat port

3. Steam Heating

4. Whole Body Stainless Steel 304

5. Air Flower

6. Button Control with inverter in Atomizer

Brief Introduction:

LPG Series High Speed Centrifugal Spray Dryer is the technology most widely used in the liquid technology shaping and in the drying industry. The drying technology is most suitable for producing solid powder or particle products from liquid materials, such as solution , emulsion, suspension and pumpable paste states, For this reason, when the particle size and distribution of the final products, residual water contents, mass density and the particle shape must meet the precise standard, spray drying is one of the most desired technologies.

Working Process:

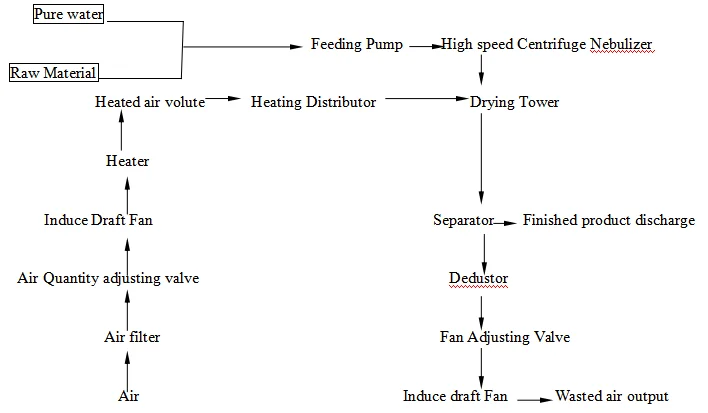

After been filtered and heated the Air enters into the air distributor on the top of the dryer .The Hot Air enters into the drying room in the spiral form and uniformly. Passing through the high-speed centrifugal Sprayer/Atomizer on the top of the tower, the material liquid will rotate and be sprayed into the extremely fine mist liquid beads .Through the very short time of contacting the heat air, the materials can be dried into the Final products .The final products will be Discharged continuously from the bottom of the drying tower and from the cyclones. The waste gas will be discharged from blower.

Features:

This equipment is composed by five systems: feeding system, heating system, drying system, discharging system and control system.

Feeding system

Feeding pump: adopt screw pump VVVF, equip Stable volt which makes feed stable.

Atomizer:

1. Rotating speed is adjustable, can be adjusted by different material and choose the best rotating speed.

2. Adopt high-speed motor to drive the atomizer directly. It saves the mechanical transmission structure. In that case, spraying will be more uniformly and noise will be lower.

3. The working power of equipment is automatic adjusted. It save the energy.

4. Construction is compact, easy for cleaning and operating and convenient for maintenance.

Heating system

The air filtered by primary and secondary filter come through the electrical heater and be heated, and then go through the high efficiency filter and come into the drying chamber. Primary filter is non-woven which is used for filtering the dust particle; secondary filter is made of non-woven bag, air-resistance ≤250pa, which is used to filter the normal dust in order to pollute the material; the class of high efficiency air filter is 10×104 which can stand high temperature.

Drying chamber

Drying chamber is composed by hot air diffuser, hot air distributor, inner of tower, outside of tower, discharging pipe, thermal insulation material, observation door, cleaning door etc. It equips air hammer to knock the wall of chamber. All the parts are made by SUS304, the thermal insulation is rock wool which is 80mm thickness.

Discharging system

The discharging systems of equipment is a cyclone separator. The cyclone can collect 98% powder product. If there is special requirements, we can equip the bag filter or water dust scrubber as the tail gas treatment.

Control system

1. The control system can realize the function as follows:

a. Stable starting and save operating.

b. Set each part of equipment and to deal with anomaly.

c. The digital display is striking. It displays all the data of equipment which make sure the normal operation of equipment.

2. PLC control system, touch screen

Drying Process:

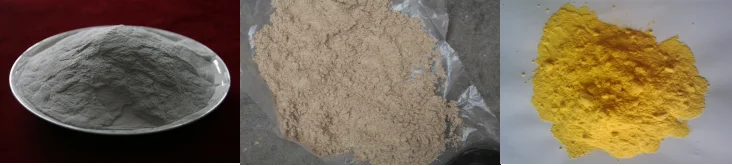

Finished Products:

Alumina Powder Herbal Powder Egg Powder

Milk Powder Soy Sauce Powder Polyphenols

Main Techinical Data:

Item | Specification |

Water Evaporation | 50kg/h |

Method of Atomizing | High Speed Centrifugal Atomizer (mechanical drive or stepless frequency speed regulation is available) |

Revolution of atomizer(rpm) | 21500 |

Diameter of Atomizing disc (mm) | 120 |

Dried Powder Recovery Rate (%) | Around≥95 |

Length of Covered Area(m) | 4.5 |

Width of Covered Area(m) | 2.8 |

Height of Tower Body(m) | 5.5 |

Hoisting height of Nozzle(m) | 2.5 |

Air input Temp | 140~350℃ |

Air output Temp | 80~90℃ |

Electric Heating Power | 60kw |

Notes: The evaporated amount of moisture is contingent upon the characteristics of the raw material, solid content and temperature of hot air at inlet and outlet. Customers can choose the heating method according to the conditions of the local energy source. | |

Machine Pictures: