What should be done if the pressed tablets can not be disintegrated within the prescribed time limit

- Share

- publisher

- Steve

- Issue Time

- Aug 26,2020

Summary

In the production process of the tablet press machine, there are often cases where the compressed tablets cannot be disintegrated within the prescribed time limit, which affects the dissolution, absorption and efficacy of the drug. What is going on? How to solve it?

What should be done if the pressed tablets can not be disintegrated within the prescribed time limit

In the production process of the tablet press machine, there are often cases where the compressed tablets cannot be disintegrated within the prescribed time limit, which affects the dissolution, absorption and efficacy of the drug. What is going on? How to solve it?

According to the industry, the general disintegration medium is water or artificial gastric juice, and its viscosity does not change much. Therefore, the main factors that affect the penetration of the disintegration medium (moisture) into the tablet are the number of capillaries, capillary pore size, surface tension and contact angle of the liquid. .

The influencing factors of tablet disintegration include the following parts:

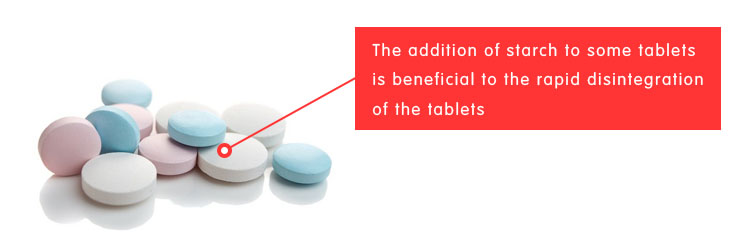

First, the compressibility of raw materials. It is reported that raw and auxiliary materials with strong compressibility are prone to plastic deformation when compressed by the tablet press machine, and the disintegration of tablets is slow. Experiments have proved that adding starch to certain tablets can often increase their porosity, significantly increase the water absorption of the tablet, and facilitate the rapid disintegration of the tablet.

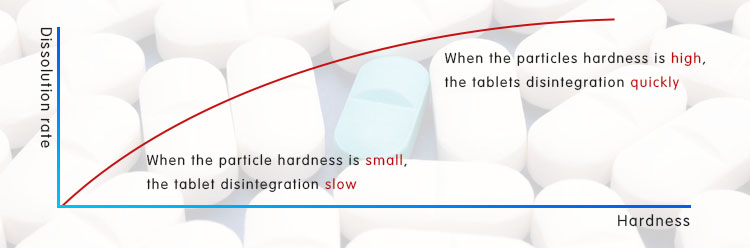

Second, the hardness of the particles. When the hardness of the granule is small, it is easy to be broken by the tablet press machine, and the tablet disintegrates slowly; on the contrary, when the hardness of the granule is large, the tablet disintegrates faster.

Third, the pressure of the tablet press machine during tablet compression. According to the industry, under normal circumstances, the greater the pressure of the tablet press machine, the slower the tablet disintegration. Therefore, the pressure of the tablet press machine should be moderate, otherwise the tablet will be too hard and difficult to disintegrate. However, the disintegration time of some tablets shortens with the increase of pressure, so different treatment is needed.

Fourth, lubricants and surfactants. The hydrophobic lubricants commonly used in tablets may also seriously affect the wettability of the tablets and accelerate the disintegration of the tablets. When the hydrophobic lubricant and the particles are mixed for a long time and the mixing intensity is greater, the surface of the particles will be more completely covered by the hydrophobic lubricant. Therefore, the pore wall of the tablet has strong hydrophobicity, which can significantly extend the disintegration time.

In addition, tablet disintegration will be affected by other excipients. For example, under the influence of starch, starch can make insoluble or hydrophobic drugs disintegrate faster, but has a poor effect on water-soluble drugs; the binder has strong binding power, and the amount of use is large, which can cause the disintegration time limit to exceed the limit; the amount of lubricant is large, The disintegration time limit can be exceeded.

The storage conditions of the tablets are also very important. It is understood that after a tablet is stored, the disintegration time is often prolonged, which is mainly related to the temperature and humidity of the environment, that is, the tablet slowly absorbs moisture, so that the disintegrant cannot exert its disintegration effect, and the disintegration of the tablet So it becomes slower. Sugar-containing tablets will obviously prolong their disintegration after storage at high temperatures or dampening.