How to improve the filling quality of capsule filling machine Pay attention to these stations

- Share

- publisher

- Steve Chan

- Issue Time

- Aug 12,2020

Summary

It is reported that some pharmaceutical companies in the process of producing capsules, due to the fine powder, will produce appearance defects during machine filling, which has always been required to remove by manual "drug selection". Through continuous optimization and debugging of the capsule filling equipment, the product rate of appearance defects is reduced, and the labor cost is greatly reduced.

How to improve the filling quality of capsule filling machine Pay attention to these stations

It is reported that some pharmaceutical companies in the process of producing capsules, due to the fine powder, will produce appearance defects during machine filling, which has always been required to remove by manual "drug selection". Through continuous optimization and debugging of the capsule filling equipment, the product rate of appearance defects is reduced, and the labor cost is greatly reduced.

"In addition to the quality of the equipment itself, the environment of the equipment, the transportation process, as well as each station will have an impact on the filling quality." A filling machine manufacturer's technical personnel said that users need to pay special attention to several positions of the equipment when operating the equipment, including the following parts.

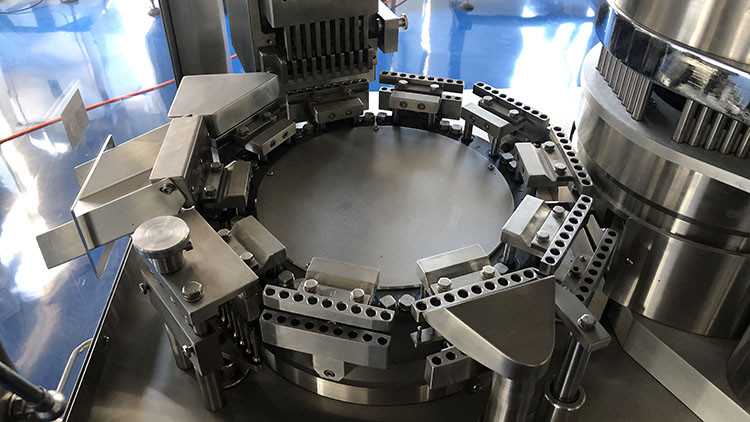

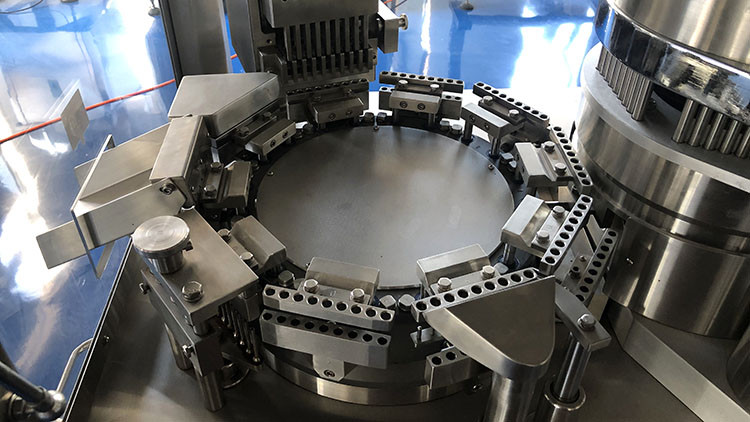

First, capsule turning and separation station. This station is the capsule feeding and separating mechanism, which is used to send the capsule into the module and separate the capsule body and capsule cap for the next step of drug filling.

The common problems of this station include poor separation and flying cap. The technicians remind that the pressure adjustment for vacuum separation should be appropriate, and it can not be too large or too small. If the pressure is too small, the phenomenon of flying cap will appear. If it is too small, it will lead to bad separation. At the same time, capsules must be purchased from regular factories and pass the inspection.

Second, filling station. This station mainly controls the filling weight of capsule contents, and the main common problem is that the weight of the contents is unstable.

The reasons mainly include three aspects: first, the metering plate and the lower module are not well aligned, which makes the weight of some finished capsules always light. The technical personnel pointed out that it is not easy to find out the problems here, and the user must do a good job in the alignment here when assembling and debugging the equipment before production; second, the gap between the isolation block on the metering plate and the metering plate is too large, which makes the medicine flow into the metering hole through the gap during filling, resulting in the weight of the capsule being too large. It is reported that the gap between the isolation block and the metering plate should be adjusted to 0.05 ~ 0.1 mm. If it is too small, it will wear the metering plate and damage the equipment.

In addition, the height of the powder on the metering plate also has a certain impact on the filling weight. If the powder height is too low, the powder can not flow into the metering hole in time, resulting in the capsule being lighter. If the height is too high, there will be too many drugs flowing into the metering plate and the weight of the capsule will be heavier.

Third, waste capsule removal station. The function of this station is to discharge the capsules with poor separation in the above station. The technical personnel said that the key here is to adjust the size of vacuum negative pressure to ensure that all the unseparated capsules can be removed, and the capsule cap in the upper module cannot be sucked away. If the vacuum is too small, the defective capsules can not be completely eliminated; if the vacuum is too large, the capsule cap will be sucked away, causing unnecessary waste and reducing the yield.

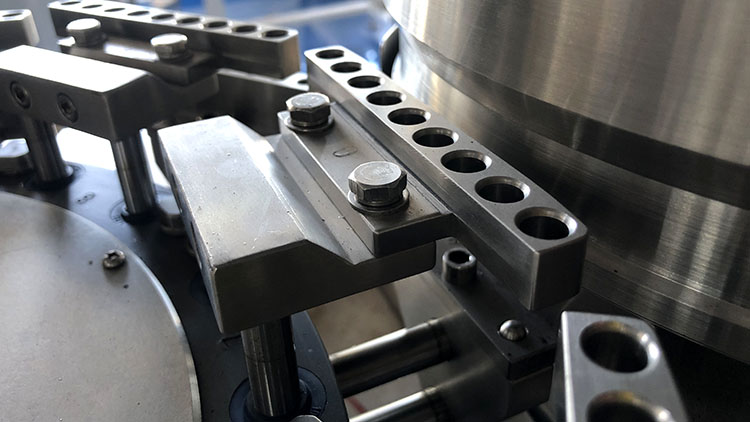

Fourth, capsule locking station. This station is to fit the filled capsule body and cap, which is an important step of capsule filling.

The common problems of this station include: capsule inserting and splitting, the main reason is that the upper and lower modules are not aligned well, the capsule body and cap are not on the same central line when the capsule is locked, resulting in damage to the capsule body or capsule cap; the locking state is poor, including the shrinkage of the capsule head, damage of the capsule, separation of the capsule body and capsule cap. The main reason of shrinkage and capsule damage is that the locking length is too short; the separation of capsule body and capsule cap is that the capsule is not locked due to the long locking length, and the capsule body capsule cap separation occurs in the process of capsule transportation.

The technician recommends that the user should measure the locking length of the capsule before commissioning the equipment so as to ensure that it is in the qualified range so as to ensure the stable production of the capsule filling machine and ensure the quality of the filling.