Regulating mechanism of automatic tablet press machine

- Share

- publisher

- Steve Chan

- Issue Time

- Jun 29,2020

Summary

The filling dose adjustment on the rotary tablet press is mainly based on the filling rail. By rotating the dial regulating plate, the shaft can be driven to rotate, and the worm shaft connected with it also rotates.

Regulating mechanism of automatic tablet press machine

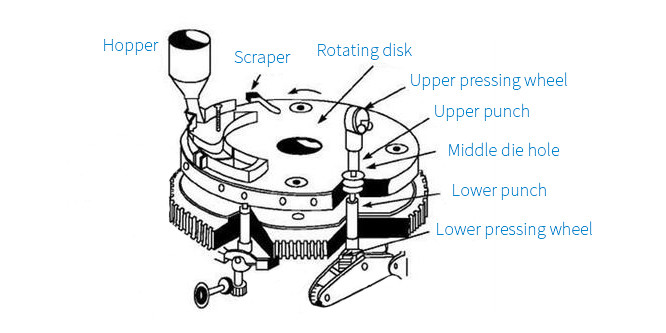

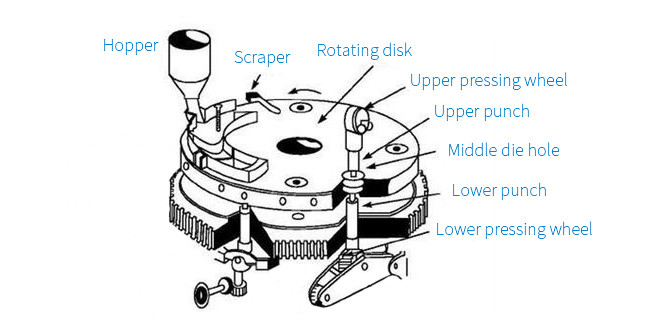

Filling regulating mechanism

The filling dose adjustment on the rotary tablet press is mainly based on the filling rail. By rotating the dial regulating plate, the shaft can be driven to rotate, and the worm shaft connected with it also rotates. When the worm wheel rotates, the internal threaded hole causes the lifting rod to move in an axial direction, and the filling rail which is firmly connected with the lifting rod also moves up and down accordingly, so as to adjust the position of the downward punch in the middle die hole, so as to meet the requirements of adjusting the filling quantity.

Up and down running guide device

Rotary tablet press, molding is based on up, down the impact of motion to complete. The axial movement of up and down is controlled by the guide rail of up and down. The up-moving guide rail can be splice together into a rotary guide plate, which is expanded as', indicating that the machine is double-chip, and there is still the same guide rail. Two tablets will be produced from the rotary table once a week. The guide plate is fastened to the upper part of the non-rotating mandrel, and the tail of the up-stroke is in contact with the curved flange of the up-stroke guide. The cross section shape of the flange of the up-stroke guide rail will be consistent with the cross section of the up-stroke shrinkage diameter. When the up-stroke rotates with the working wheel, it will be subject to the control of the guide rail and produce axial motion. The downstroke guide rail is relatively simple, which is inlaid on the frame body, and the downstroke depends on the weight and pressure of the upstroke on the downstroke guide rail surface. According to the force of the object in the die, the up-rushing downward guide rail is designed according to the cosine curve, so that the acceleration of the up-rushing is zero, in order to reduce the impact and increase the service life of the die. As the upstroke moves along the upstroke rail, the upstroke slowly rises from low to high, gradually exits through the middle die hole, and reaches the highest point. As the upstroke begins to walk in parallel tracks, the downstroke rises on the upstroke, gradually reaching the highest point, and ejecting the pill. When the upper charge stays at the highest point in the downward rail, the lower charge starts to fall, and then the lower charge runs on the filling rail. During this period, the middle die hole is completely exposed to the covering area of the feeder, completing the feeding process. When the upper punch reaches the control area of the downward rail, the upper punch gradually descends into the middle die hole for the tablet pressing process. At this time, the lower punch is at the lowest point but does not leave the middle die hole, so the bottom of the hole is always sealed.

Pressure regulating mechanism

The actual application of pressure to a drug on a rotary tablet press does not depend on the running rail. The upper and lower rushing are placed on a pair of upper and lower rollers on the rack during the pressurization stage (at this time, the upper rushing tail is separated from the upper rushing rail).

The eccentric regulating pressure mechanism is an eccentric regulating pressure mechanism. The upper pressing wheel is mounted on an eccentric shaft. By adjusting the nut, the pressure of the compression spring is changed, and the swing Angle of the rocker arm is changed at the same time, so as to change the eccentric bearing of the eccentric shaft, so as to reach the lowest point position of adjusting the upper press wheel, and thus change the lowest point position of the upper thrust. When the pressure of the die is too high, the buffer spring will bear too much force, which will make the micro switch move and stop the machine, thus achieving the function of overload protection.

Another kind of pressing wheel eccentric adjusting mechanism, when loosening the setting screw, using the plum handle to rotate the worm shaft, rotating the worm wheel, can also change the eccentric axis eccentric azimuth, in order to achieve the purpose of changing the highest position of pressing wheel, so as to adjust the highest position of pressing plate at the moment.

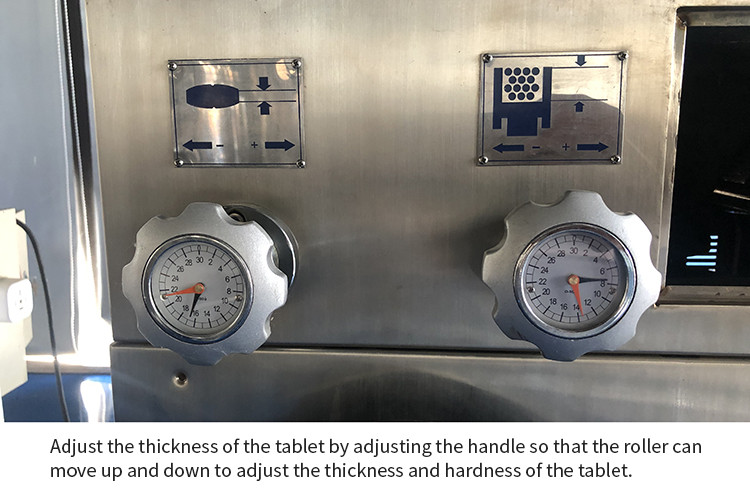

The upper and lower pressure wheels are mounted on the upper and lower pressure wheels respectively. One end of the diamond pressure wheel stand is connected with the regulating mechanism respectively, and the other end is connected with the fixed bracket. Adjusting the handwheel can change the upper and lower position of the upper press wheel frame, so as to adjust the depth of the upper punch into the middle die hole. Adjust the thickness of the tablet by adjusting the handle so that the roller can move up and down to adjust the thickness and hardness of the tablet. The pressure is controlled by the pressure cylinder. This kind of pressure and pressure regulating mechanism can ensure the pressure increase stably, and can maintain a certain time at the maximum pressure, it has a certain effect on the compression of granular materials and the discharge of air, so it is suitable for high-speed rotary tablet press.