Method for preparing spongy graphene by freeze dryer

- Share

- publisher

- Xavier

- Issue Time

- Oct 30,2019

Summary

Method for preparing spongy graphene by freeze dryer

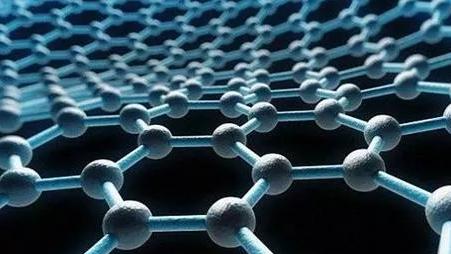

Graphene is a honeycomb two-dimensional lattice structure lamellar nano-material formed by closely mixing carbon atoms in sp2 hybrid mode. Since its discovery in 2004, graphene has attracted the attention of researchers with its excellent physical and chemical properties. It has rapidly become a research hotspot in the fields of physical chemistry, material energy, life sciences and information technology. Graphene's special monoatomic layered structure gives it a very large specific surface area, and sp2 hybridization gives it many wonderful properties and excellent physicochemical properties. In terms of mechanical properties, it has high strength and high modulus; in thermal properties, it has high thermal conductivity; in terms of electrical properties, it has high electrical conductivity. In addition, Graphene has some special properties, such as: Graphene has quantum Hall effect and ferromagnetism at room temperature.

Since the discovery of graphene, scientific researchers have been trying to prepare graphene by different methods. At present, according to the principle of preparation, it can be divided into physical methods and chemical methods. The physical method, that is, the method of mechanical peeling, can be further divided into a micro mechanical peeling method and a solvent peeling method. The chemical methods mainly include a graphite oxide reduction method, a thermal decomposition SiC method, and a chemical vapor deposition (CVD) method.

Today, the preparation of three-dimensional graphene has attracted great interest from researchers. The three-dimensional graphene is usually synthesized by hydrothermal-solvent method. In this process, a reducing agent is added to the solvent to reduce the graphite oxide at a certain temperature, so that the synthesized graphene has low crystallinity and volume shrinkage. It is prone to knotting and the yield is not high. There has also been reported a method of freeze-drying graphene to obtain three-dimensional graphene, but graphene is not easily dissolved in a solvent, and thus agglomeration occurs.

The invention provides a method for preparing spongy graphene by freeze-drying method. The graphene obtained by the method is porous and has a large specific surface area, has a three-dimensional sponge shape, low density, ultra-light and stable structure, and can be used as Adsorption materials and composite materials broaden the application.

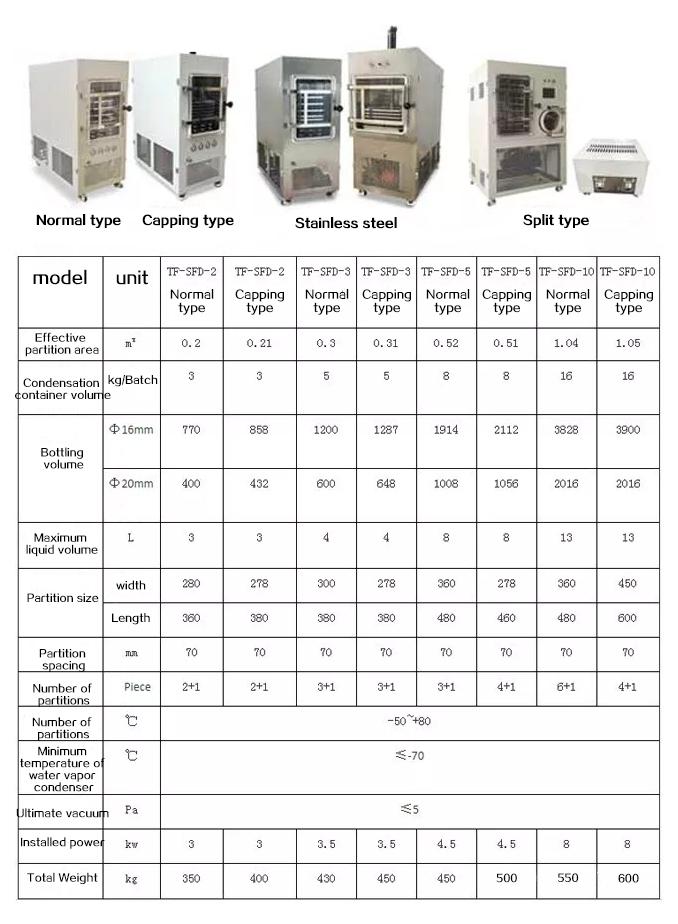

Graphene freeze dryer equipment

A method for preparing spongy graphene by freeze-drying method, comprising:

(1) Ultrasonic blending of raw materials in an ice bath

Add natural graphite to the ice bath ultrasonic concentrated H2SO4 in 15-60min, then add NaNO3, then add potassium permanganate KMnO4 in 15-60min, wait for the potassium permanganate to be added, start the reaction, 0.5-1h, Ensure that the temperature of the system is not higher than 10℃ to obtain a mixed solution;

(2) Oxidation of raw materials in a water bath

The above mixture is stirred in a water bath at 30-35℃ for 0.5-1.5 h, deionized water is added to the mixture, heated to 95-100℃, stirring is continued for 20-30 min, then deionized water and hydrogen peroxide are added until The solution turned bright yellow, no bubbles were generated (to obtain graphite oxide), and then separated, washed, freeze-dried, and subjected to low-pressure heat stripping to obtain spongy graphene. The ratio of natural graphite, concentrated H2SO4, NaNO3, and potassium permanganate KMnO4 in the step (1) is 2g: 50ml: 1g: 7g, that is, a slight excess of KMnO4 and concentrated H2SO4, and graphite and KMnO4 are slowly added to the concentrated H2SO4. The purpose is to ensure that the graphite is sufficiently oxidized and intercalated at a later stage.

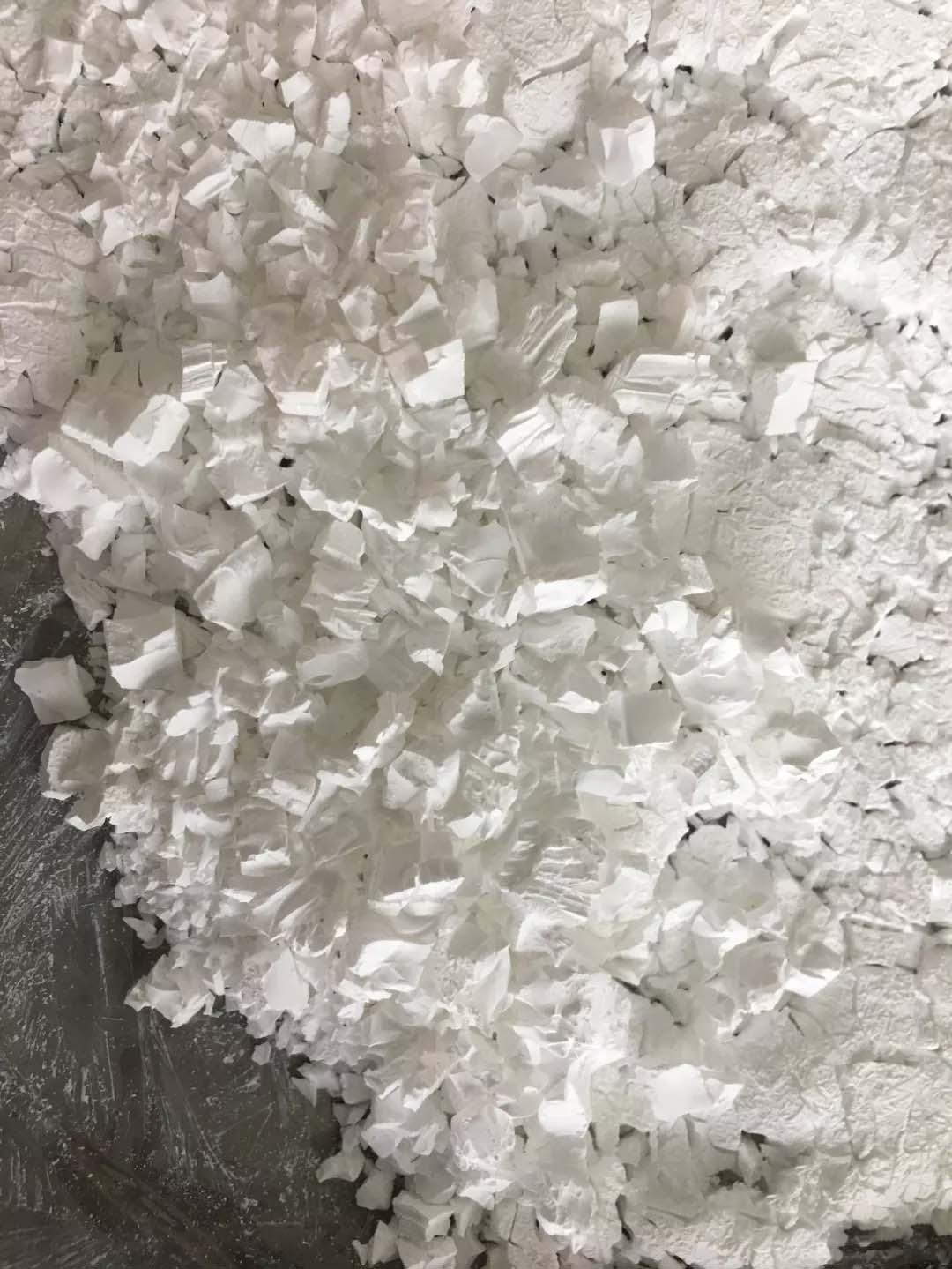

Using graphite oxide as the precursor, the aqueous solution of graphite oxide is directly freeze-dried to ensure that the sample remains fluffy. Finally, the spongy graphite oxide is stripped and reduced by low pressure heat to obtain spongy graphene. In this process, only temperature, pressure and time need to be adjusted. Sponge graphene with different morphologies and properties can be obtained with other parameters, and no toxic chemical reducing agent is used, which avoids environmental pollution and is easy to achieve mass production.

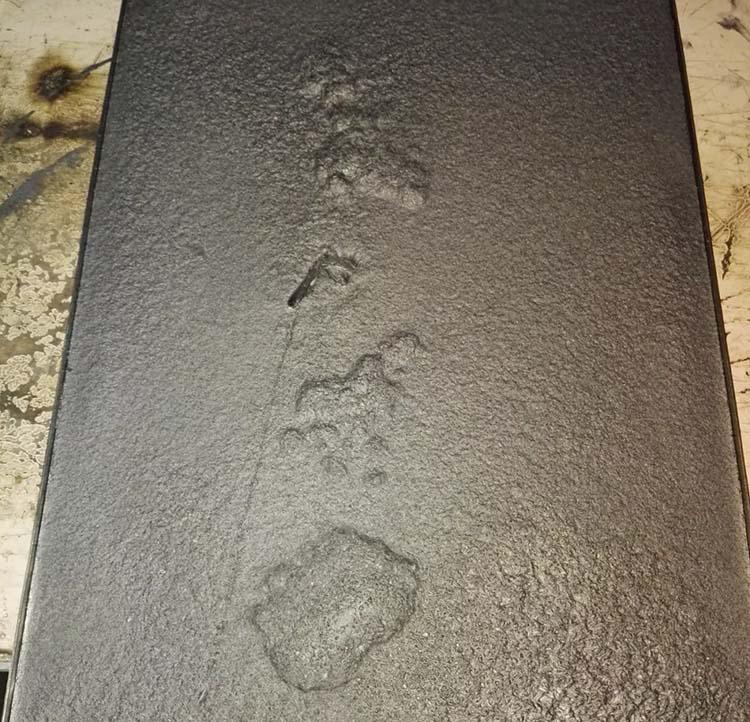

LTPM CHINA manufacturers graphene freeze-dried case!

Advantages of lyophilizers for the preparation of graphene:

(1) The obtained graphene is porous and has a large specific surface area, exhibits a three-dimensional sponge shape, has low density, is ultra-light and structurally stable, and can be used as an adsorbent material and a composite material, thereby broadening its application prospect;

(2) By changing the reaction parameters of the vacuum freeze-drying and low-pressure heat stripping reduction stages, the macroscopic shape, microstructure, conductivity and adsorption properties of the three-dimensional spongy graphene can be changed;

(3) The preparation process is simple, easy to operate, and the preparation cycle is short, fast and efficient;

(4) The raw materials used are widely sourced and low in cost. It is environmentally friendly and energy efficient, and can be applied.

Case of lyophilized white graphene produced by LTPM CHINA