10 Easy Steps for Cleaning Your Tablet Press

- Share

- publisher

- Xabier

- Issue Time

- Oct 22,2019

Summary

10 Easy Steps for Cleaning Your Tablet Press

Nothing can slow production down like equipment that malfunctions or stops working altogether. Performing regular, preventative maintenance of equipment is essential and helps keep pharmaceutical tablet presses functioning efficiently and smoothly.

Tablet presses that are not well maintained can cause a multitude of problems, creating defective products that are mal-formed, contaminated or contain improper dosages. One of the most important steps to maintaining your tablet press is keeping it clean. It’s also important to have systems in place to validate and document the cleanliness of the equipment.

10 Key Steps For Cleaning Tablet Presses:

1. Clean the Exterior: Wipe away all visible dirt on the exterior of the press and vacuum off any excess formulation. Do not use compressed air to blow off excess powders. Compressed air can trap powders in hidden housings, crevices and pockets causing problems down the line.

2. Visual Inspection: Examine the press to assess the condition of the parts. Look for signs of wear or damage on tablet punches and punch heads, and earmark any parts that need repair or replacement.

3. Prepare the Press for Cleaning: Carefully dismantle removable machine parts for thorough cleaning. Tooling, punch heads, feed frames, guards and plates can often be removed for cleaning purposes.

4. Use the Proper Equipment: Stiff nylon punch guide brushes and die seat cleaning tools help to access hidden areas of the press that might contain traces of debris. It’s important not to use any unnecessary force, since tablet presses are delicate and can be easily damaged if not carefully handled.

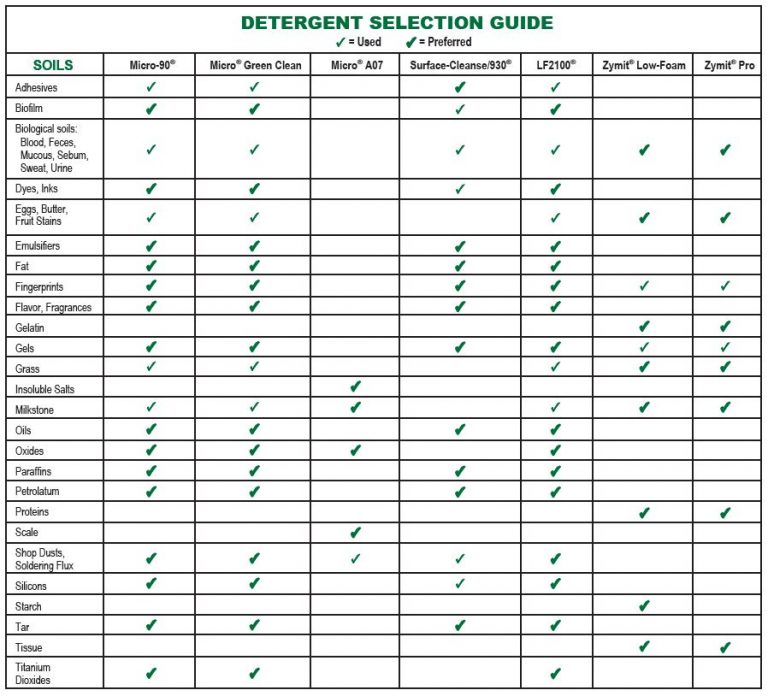

5. Choose the Right Cleaner: Your choice of cleaner will depend largely upon the soils that are on your press. Are you removing Oils? Gels? Starches? Enzymes? Use this chart to help match a cleaner to the soil. You’ll also want to consider the surface you are cleaning to be sure you are choosing a compatible cleaner.

6. Set Up a Proper Cleaning Method: In addition to using the right cleaning product, it’s also important to consider other variables to establish your cleaning protocol. All of the following should be considered:

a. Amount of Detergent

b. Temperature

c. Dwell time

d. Cleaning method

e. Type of water

7. Rinse: Thorough rinsing should follow the cleaning. Rinsing removes any excess detergent left on the item. For critical cleaning applications it is best to use deionized or distilled water, as rinsing with ordinary water may introduce new contaminates.

8. Validation: Cleaning validation helps identify if there is any remaining residue from soils and cleaners, and helps prevent contamination. Quantitative validation methods, available from most manufacturers, should be used for critical cleaning applications.

9. Disinfect: If required, disinfection should be done after the press is cleaned and soils are removed.

10. Dry Parts Thoroughly: Parts should be completely dried to prevent rusting, corrosion or discoloration.

Setting up an established cleaning routine for your tablet press will help keep it running smoothly and efficiently, and may even extend the serviceable life of your equipment. Regular cleaning will also help prevent regulatory issues and product problems. A few small steps spent on regular cleaning can be a giant leap toward savings and efficiency in the long run.

For more information on setting up a cleaning regimen and choosing the right cleaner for your application, visit International Products Corporation’s website or contact one of our technical specialists for assistance.